Rumored Buzz on Sand Blaster Harbor Freight

Wiki Article

Unknown Facts About Grit Blasting

Table of ContentsThe smart Trick of Black Diamond Blasting Sand That Nobody is Talking AboutThe Basic Principles Of Pressure Washer Sandblaster The Ultimate Guide To Sand Blaster For SaleThe Greatest Guide To Mobile Sandblasting Near MeThe 4-Minute Rule for Sand Blaster For SaleThe smart Trick of Abrasive Blasting That Nobody is Talking About

Wet rough blasting [edit] Wet rough blasting uses water as the fluid relocating the abrasives. The benefits are that the water traps the dirt created, as well as lubes the surface. The water supports the influence on the surface area, decreasing the removal of audio product. Among the original leaders of the wet unpleasant process was Norman Ashworth that found the advantages of utilizing a damp process as a strong choice to completely dry blasting.

Reduced impregnation of blowing up product right into the surface, dust decrease and also the elimination of fixed stick can cause a spick-and-span surface - sand blaster harbor freight. Wet blasting of light steel will certainly cause immediate or 'flash' rust of the blown up steel substrate because of the visibility of water. The lack of surface recontamination additionally allows the use of solitary equipment for multiple blowing up operationse.

The smart Trick of Grit Blasting That Nobody is Talking About

A variant of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this procedure pressurized air is added to the water in the nozzle generating a high speed haze, called "vapor". This procedure is also milder than damp blasting, allowing breeding surface areas to be cleaned while retaining their capacity to mate.Mixing particles with water substantially lowers dust. Grain blasting is the process of getting rid of surface down payments by using great glass grains at a high pressure without damaging the surface.

In eliminating paint for vehicle body work, bead blasting is preferred over sand blasting, as sand blasting tends to create a greater surface profile than bead blasting. Bead blasting is typically utilized in producing a consistent surface area coating on machined parts. It is in addition utilized in cleansing mineral samplings, the majority of which have a Mohs firmness of 7 or less and would thus be damaged by sand.

Some Known Facts About Sandblaster For Sale.

The very first blast wheel was patented by Wheelabrator in 1932. In China, the first blast wheel was sand blaster harbor freight built around the 1950s, Qinggong Equipment is one of the earliest manufacturers of blast wheel. Hydro-blasting [edit] Hydro blasting is not a form of abrasive blasting as no unpleasant media is utilized. Hydro-blasting, frequently understood as water blasting, is commonly utilized because it generally needs only one driver.This method is excellent for cleaning up internal and outside surface areas because the driver is normally able to send the stream of water right into places that are hard to get to utilizing other techniques. An additional advantage of look at this website hydro-blasting is the capacity to regain and recycle the water, lowering waste and also mitigating ecological influence.

Greater stress are commonly required. One of the most usual micro-abrasive blasting systems are commercial bench-mounted devices including a power supply and also mixer, exhaust hood, nozzle, as well as gas supply. The nozzle can be hand-held or component mounted for automatic operation. Either the nozzle or part can be relocated automatic procedure.

Excitement About Sand Blaster Harbor Freight

Automated blasting is often just an action in a larger automated treatment, usually involving various other surface area treatments such as prep work as well as layer applications.The air compressor offers a big volume of high stress air to a solitary or multiple "blast pots". Blast pots are pressurized, tank-like containers, loaded with abrasive product, made use of to enable an adjustable amount of blowing up grit right into the main blowing up line. The variety of blast pots is determined by the volume of air the compressor can provide.

Others are receptacle-fed kinds making them light-weight and also a lot more mobile. In damp blasting, the abrasive is presented into a pressurized stream of water or other liquid, developing a slurry. Damp blowing up is commonly made use of in applications where the minimal dirt generation is desired. Mobile applications may or may not reuse the abrasive.

Harbor Freight Sand Blaster Can Be Fun For Everyone

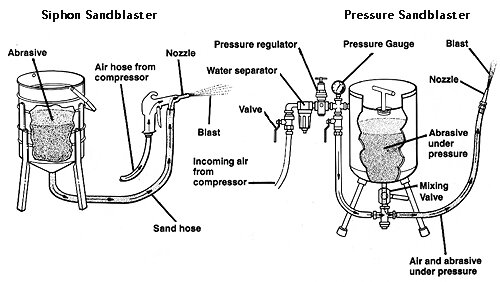

There are three systems normally used in a blast closet. 2, siphon and also stress, are dry and also one is damp: A siphon blast system (suction blast system) uses the compressed air to produce vacuum in a chamber (called the blast gun). The negative pressure draws unpleasant right into the blast gun where the compressed air routes the abrasive through a blast nozzle.

Silicon carbide and boron carbide nozzles are more use immune and also are commonly used with more challenging abrasives such as aluminium oxide. Inexpensive rough blowing up systems and also smaller sized closets use ceramic nozzles.

More About Pressure Washer Sandblaster

The vessel is pressurized to the very same stress as the blast tube affixed micro sandblaster to all-time low of the pressure vessel. The rough is metered right into the blast pipe and also shared by the pressed gas through the blast nozzle. Wet blast cupboards utilize a system that infuses the abrasive/liquid slurry right into a pressed gas stream.Report this wiki page